A Quick Guide To 4 Common Decoration Methods

Blank brandable goods are great, but it’s the decoration that makes them customizable and truly unique. This quick guide to four of the most popular decorating methods – screen printing, embroidery, laser engraving and die casting – will help you understand how each approach works and get an idea which is best for your promotional projects.

SCREEN PRINTING

Screen printing (aka silk screening) is used to transfer images onto blank products, such as T-shirts, glass, electronics and banners, using ink or dye, a mesh metal screen and a squeegee. Ink is forced through the metal screen onto desired areas using a stencil for each color in the design.

Screen printing is one of the most popular methods of decorating blank products, especially fabrics and paper goods, and it’s a fast, affordable way to print sizable orders with relatively quick turnaround.

Screen-printed T-shirts have served as walking billboards for businesses, brands, benefits and events of all sizes for more than 60 years. Screen-printed T-shirts in all kinds of fabrications, styles and colors have become one of the most-popular clothing items – there’s even a market for worn T-shirts in vintage wear.

Screen Printing Quick Facts:

- A screen-printed T-shirt will last through 40-50 washes.

- Best fabrics for screen printing are cotton, cotton blends and polyester. (Not suitable for coated fabrics.)

- Produces bold, vibrant colors and clean, sharp edges.

- Best-suited for one- or two-color designs (more colors mean more costs).

- Not ideal for complex/detailed designs.

Screen Printing Is Ideal For:

- Graphic T-shirts to advertise local businesses, events, bands, school spirit, etc.

- Teamwear

- Work uniforms

- Safety apparel

- Paper, canvas and artwork

EMBROIDERY

Embroidery is the use of needlework to apply decorative designs to fabrics and other materials by stitching thread or yarn into another material. It’s not the same as sewing, which refers to the process of stitching the actual product together. Embroidery can be achieved by hand, assisted by a machine or automated for commercial purposes.

Embroidery projects may consist of a simple one-color running stitch used to outline designs or a multicolor project outlined in a more complex chain stitch. Embroidery can also provide a 3D effect with threads forming imagery that protrudes above the fabric’s surface. It may also feature embellishments like beads, charms, rhinestones or sequins.

Embroidery is one of the longest-lasting decoration applications and also allows for complex detail. When striving to achieve a professional look that’s durable and eye-catching, embroidery may be just what you’re looking for.

An embroidered design may last the lifetime of a product. Unlike screen printing, which can fade over time as a garment is washed and worn, embroidery won’t fade. Distortion can occur, however, if threads snag, pull or come loose. For this reason, it’s important to wash embroidered goods gently or by hand.

Embroidery Quick Facts:

- Best fabrics for embroidery are cotton, canvas, fleece, linen and denim.

- Thin/delicate fabrics, such as silk and rayon, should not be embroidered.

- Not ideal for very small designs or very large gradient designs.

Embroidery Is Ideal For:

- Polo shirts

- Robes

- Tote bags and wallets

- Accessories, such as gloves, scarves, ties, caps and slippers

- Home items like tablecloths and table runners, napkins, curtains, pillowcases, bedding and towels

LASER ENGRAVING

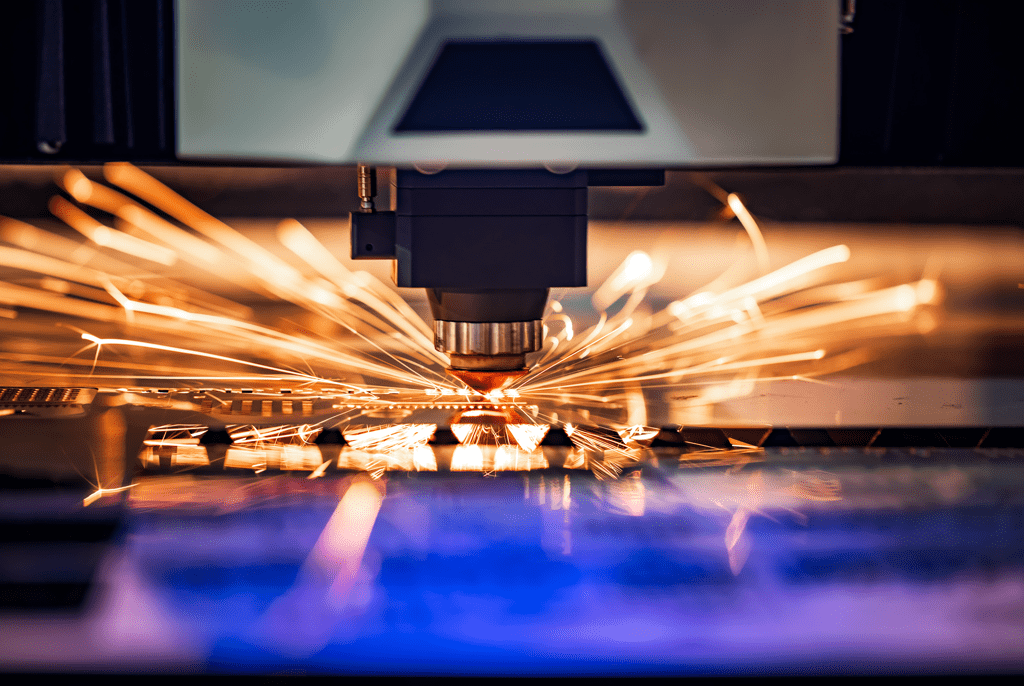

Laser engraving is a modernized version of the age-old art of engraving, now performed by computerized machines that replace the need for hand work, making it faster and more economical. Today, laser engraving is the most common means of engraving at a commercial level.

The laser is programmed for precision, and its point focuses on just a fraction of a millimeter, so it produces a clean finish every time. By generating heat to pinpointed areas, the laser causes the surface material to vaporize, and deep cavities will appear. Popular promotional products that may be engraved or laser-engraved include trophies, awards, plaques, nameplates, glassware and wine bottles, as well as jewelry, such as rings, lockets, watches and necklaces.

Engraving is not to be confused with etching, which is similar, but rather than producing deep grooves by removing material, etching melts the surface to create raised marks. Engraving is typically done on metals, while etching is usually used to customize glass, stones or crystal. Both are high-heat processes that produce permanent markings.

Laser Engraving Quick Facts:

- Depending on the material used, how deep the engraving is and how often it’s used or worn, laser engraving should last the lifetime of the product.

- Hard materials, such as stone, wood, glass, acrylic and metal are the best media for laser engraving, but it can also be done on leather, plastic and paper. (Not all materials can be laser-engraved, so it’s important to check first.)

- Produces high precision and intricate details.

Laser Engraving Is Ideal For:

- Metal drinkware

- Awards, trophies, plaques and nameplates

- Personalized leather items, such as wallets, bags, purses and journals

- Jewelry, such as rings and wedding bands, necklaces, lockets, bracelets and watches

DIE CASTING & STRIKING

First invented in the mid-1800s, die casting and striking is a method widely used to make metal parts for manufactured goods and machinery. Most consumer goods, from door handles to power tools to children’s toys to golf clubs, contain die-cast components. When it comes to promotional products, die casting and striking are used to fashion custom items like awards, coins, medallions, belt buckles, model toys and pins.

Die casting is the process of manipulating metals into desired shapes by pouring molten metal into molds to create objects or parts. The most common metal casting materials include aluminum, magnesium, pewter, zinc, brass and copper. Time and pressure typically cause the liquid metal to solidify in a matter of seconds and take the shape of the mold. The result is a sturdy object that won’t lose its shape.

Die casting is a highly accurate way to duplicate an object’s dimensions, such as a 3D paperweight in the shape of a company emblem. Once the desired object is formed, details are added and excess material removed via metal striking, using mallets, chisels or other tools, while the metal is still hot and pliable. (Keep in mind that metal stamping is a different process that involves the use of upper and lower molds/dies to stamp an imprint into a product, such as a blank metal coin or name plate.) A single die lasts for about 80,000 shots – or 80,000 times of the mold being injected with metal – making this method ideal for mass production.

Since the goal is a solid object, 3D printing may be considered as an alternative to die casting. While 3D printing does not require the use of dies/molds, there are minimal costs upfront and a lower barrier to entry, but it generally costs more per unit for 3D printed products than die casting. Also, while 3D printing saves time, die casting offers a wider range of options, as not all materials can be 3D printed, particularly metals.

Metal Die Casting & Striking Quick Facts:

- Great way to create complex or unusual shapes.

- Uniform quality ideal for mass production.

- Fewer steps from raw material to finished product.

- Requires die/mold creation, which means longer lead times and changes to orders are costly and time-consuming, making it less economical for smaller orders.

Die Casting and Striking Are Ideal For:

- Awards and recognition

- Memorabilia/collectibles

- Accessories for wearables, like belt buckles and bag hardware

- Consumer electronics

- Cookware (stainless steel skillets and cast-iron pans)

Contact your promotional products distributor partner to learn more about decorating methods and what options might be best for your next project.